Recent

-

-

Introducing Version 4.0.0 of the MicroStrain ROS Driver

Jan 29, 2024 /

-

-

-

Enhancing Vision-Based Robots with IMUs

Dec 19, 2023 /

-

-

-

MicroStrain to Join the HBK Family

Sep 18, 2023 /

-

-

-

Four Ways to Improve Your IMU Performance

Jun 30, 2023 /

-

Applications

How Auto-Adaptive Technology in Inertial Sensors is Improving Precision

- By Collin /

- Published Tue, 02/14/2017 - 13:00

By Fritz Martin, Engineering Manager of Inertial Products

Inertial sensors are increasingly being incorporated into a growing list of applications, including antenna pointing, GNSS navigation, platform stabilization, flight tracking, regime monitoring, autonomous vehicles, robots, and package delivery systems.

This means reliability and performance is more important than ever, especially when determining the attitude (pitch, roll and yaw) of the sensor from magnetometer, accelerometer and gyro data.

An accelerometer at rest with respect to the earth gives a signal that is proportional to the acceleration of gravity and the cosine of the angle between its sensitive axis and the upward direction. It is for this reason that attitude sensors commonly use multiple accelerometers to estimate pitch and roll angles. However, there is a significant limitation to this method—the implicit assumption being that the accelerometers are moving at constant velocity. In many applications, that approximation is invalid.

A greater degree of precision is needed. Sensors using auto-adaptive features, such as our latest generation of 3DM-GX5 series of inertial sensors, help address this problem.

How does this work? An onboard estimation filter using accelerometer to estimate pitch and roll angles is used, but an auto-adaptive feature smoothly rejects errors due to the violation of the “sensor-at-rest” approximation. It then adjusts the responsiveness of the filter to account for varying vibration levels.

The same auto-adaptive feature is used to reject transient disturbances in the magnetometer signal when the magnetometer is being used for heading reference. This limits heading errors due to the sensor platform passing close to a magnetic field source, for example.

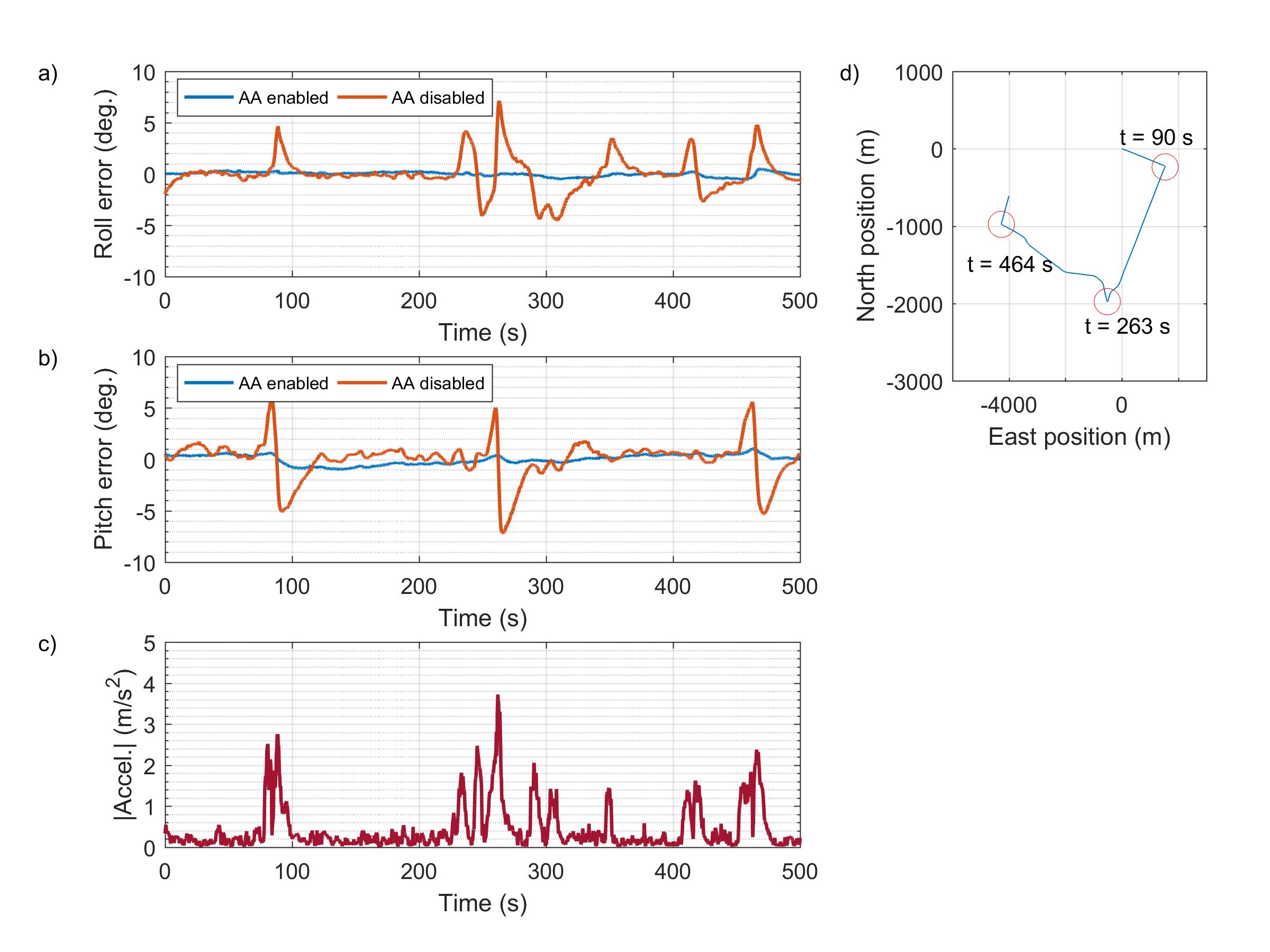

Why does all this matter? The graph below shows the results from a real world road test. It demonstrates how the auto-adaptive features drastically improve pitch and roll accuracy under dynamic conditions. This test uses our 3DM-GX5-25 AHRS. In this test, the in-run pitch and roll RMS accuracies are ±0.47° and °/±0.21° respectively which is very good for an AHRS undergoing linear accelerations. Even better results can potentially be realized when a velocity measurement is available from a GNSS/INS such as our 3DM-GX5-45.

What are your thoughts on inertial sensors and their use in additional applications? Leave a comment below!

Pictured are potential benefits of using auto-adaptive filtering for pitch and roll estimation on a dynamic platform. In this trial, two GX5-25 AHRS sensors were mounted side-by-side on an automotive platform. One of the units was configured with the auto-adaptive feature enabled, the other unit was configured with the auto-adaptive feature disabled. The new GX5-15, GX5-25 and GX5-45 each includes the auto-adaptive filtering feature. Error with respect to the reference in a) the roll angle and b) the pitch angle. The magnitude of the lateral acceleration as measured by the reference unit is shown in c). Portions of the trajectory corresponding to higher lateral acceleration are indicated in d). Maximum pitch and roll deviation with AA enabled are ± 0.5 deg. and ± 1.0 deg. respectively, versus ± 7.1 deg. and ± 7.2 deg. respectively with AA disabled.