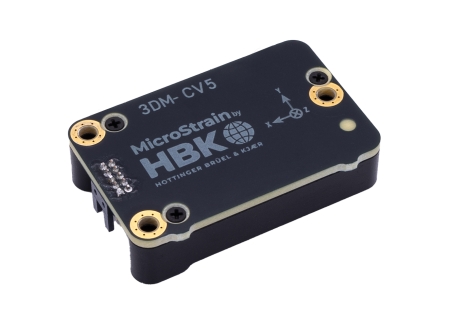

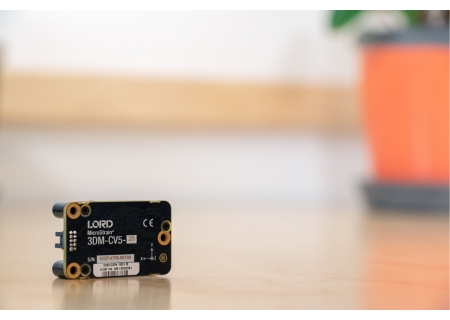

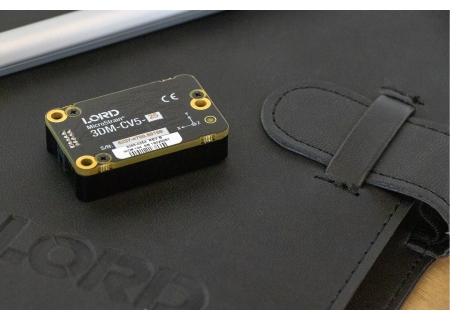

MicroStrain 3DM-CV5-AHRS Industrial Attitude Reference Sensor, OEM Package

The 3DMCV5-AHRS is a value focused AHRS designed to balance cost and performance.

Specs

Sensor

-

High Performance Accelerometer

- 100 µg/√Hz (8g standard)

- 2g, 4g, 20g, 40g options

-

Super-stable Gyro

- 8 dph in-run bias (-40 to +85°C)

- Offset temperature hysteresis 0.05°/s

- ARW 0.3°/√hr

Operation

- IMU sampling rate up to 1000Hz

- Auto-adaptive EKF output rate up to 500Hz

- In-run auto-mag calibration features

- Independently configurable IMU and EKF outputs

- SensorConnect software for configuration, control, display, and logging

Package

- CNC Anodized Aluminum

- Precision alignment features

- Highly compact and low profile

- 38.0 mm x 24.0 mm x 9.7 mm

- 13.0 grams

- USB and TTL UART interface (up to 921600 BAUD)

- –40 to +85 °C operating temperature range

Use Cases

Low-noise, low latency, and linear MEMS gyros and accelerometers result in accurate and stable attitude tracking

Rugged machined aluminum industrial packaging provides reliable performance in high-vibration and shock environments

Compact OEM versions for embedded applications permit lower cost without losing accuracy

Low-noise, low-drift MEMS gyros and accelerometers result in accurate and robust PVA (Position, Velocity, Attitude) outputs during sharp turns, high winds, etc.

Exceptional IMU performance and robust anomaly rejection by the EKF aids navigation under GNSS outage or denied environments

Fully calibrated and temperature compensated guarantees stable performance in outdoor operating temperature ranges even with high levels of fluctuation

Low-noise, linear, and stable MEMS gyros and accelerometers enable superior heading accuracy during turns & bumps

Auto-adaptive Kalman Filter algorithms provide exceptional dynamic performance

Auto self-calibration and automatic anomaly rejection make units with magnetometer reliable and accurate heading reference

Fully calibrated and temperature compensated IMUs provide stable performance in demanding environments

Documentation

General Documentation

Technical Notes

- Interface Control Drawing

- C-Series Connectivity Board Interface Control Document

- Inertial product comparison

- Inertial Sensor Utils User Manual

- Auto-Adaptive Dynamic Roll & Pitch Performance

- When to use “Capture Gyro Bias”

- Using a GX5 with Bluetooth RS-232 Adapters

- Using a Hardware Datalogger with Inertial Sensors

Downloads

Software/Firmware

More

- Micro D-to-USB Communication and Power Cable

- Micro D-to-RS232 Communication and Power Cable

- Craft Cable with Micro DB9 and Flying Leads

- C-Series Connectivity Board Drawing (STP File)

- 3DMCV5 3D Model (STP File)

- Dewesoft Inertial Sensor Manual

- 6212-3006 OEM Cable Kit

- 6212-3010 DEVELOPMENT KIT, RS232, INERTIAL C-SERIES

- 6212-3009 DEVELOPMENT KIT, USB, INERTIAL C-SERIES

Software

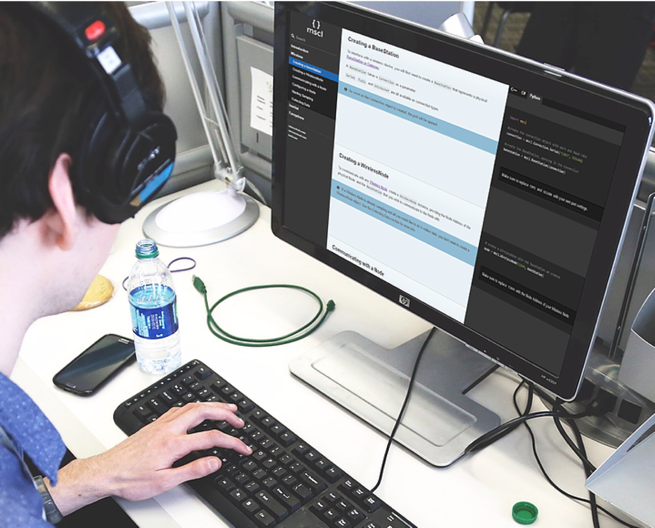

SensorConnect

Free

SensorConnect is the next generation in desktop sensing software.

From configuration of nodes and starting networks, to collecting and analyzing data in real-time, SensorConnect provides a modern, powerful experience with our Wireless, Inertial, and Displacement products.

Using our intelligent data collection and graphing algorithms, you are able to visualize massive amounts of data instantly, and then zoom in on points of interest just as fast.

Built in MathEngine functionality allows for both real-time and post-processed math, such as generating FFTs, averages, RMS, etc.

{MSCL}

Free and open source API

The MicroStrain Communication Library (MSCL) makes it simple to write code that interacts with our Wireless, Inertial, and Displacement sensors.

MSCL is completely open source and hosted on GitHub under the MIT license.

Full documentation, example code, and a quick start guide are provided to help you get started.

Available for C++, Python, and .NET.

MIP Monitor

Free Legacy Software

MIP Monitor is PC software specifically designed for our Inertial products.

Configure Inertial nodes, start sampling, and view data in real time.

MIP packets can also be viewed in their raw form to aid in development of custom software.