(Cary, N.C., Aug. 24, 2017) - LORD Sensing MicroStrain, a global leader in developing embedded sensing systems, has once again expanded its portfolio of sensors for the industrial off-highway, agriculture, mining and construction markets with the introduction of new offerings to complete its 3DM®-GX5 family of inertial sensors

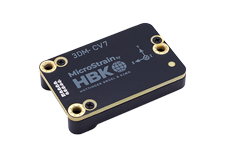

The new additions to the award-winning 3DM-GX5 sensor family are the 3DM-GX5-10 Inertial Measurement Unit (IMU) and the 3DM-GX5-35 Attitude and Heading Reference System (AHRS) with GNSS. The new models provide customers cost saving options for applications that do not require on-board Extended Kalman Filters (EKF). The new sensors utilize the same high performance industrial grade Micro-Electro Mechanical System (MEMS) technology as the other members of the GX5 family.

The 3DM-GX5-10 IMU includes direct measurement of acceleration and angular rate. The product offers easy integration via comprehensive and fully backwards-compatible communication protocol as well as a robust forward compatible MIP packet protocol. Further, it is fully temperature-compensated and calibrated over the operating temperature. This out-of-the-box solution reduces development time and volume discounts are available.

The 3DM-GX5-35 AHRS with GNSS also offers easy integration via comprehensive and fully backwards-compatible communication protocol. It combines direct measurement of acceleration and angular rate along with a multi-constellation state-of-the-art broadband GNSS receiver. Static roll-pitch-yaw computations from a simple complementary filter are available as reference outputs. All sensors are fully temperature-compensated and calibrated over the operating temperature. This product offers an economical combination of AHRS with GNSS for use in applications where customer require a reference or use their own Kalman Filters.

The LORD Sensing MIP Monitor software can be used for device configuration, live data monitoring and recording. Alternatively the MIP Data Communications Protocol is available for development of custom interfaces and easy OEM integration.

“We have a large portfolio that shares the same software and protocol, allowing customers to move up and down the product line where they need varying levels of precision with MEMS Inertial Sensors or GNSS,” says Fritz Martin, Inertial Engineering Manager, LORD Sensing. “Customers can stay within the LORD family and dial into their needs. LORD continues to develop its family of products using the same backbone and backwards compatibility of previous generations.”

Both of these products join the well-established and market-proven products already found in this line. The GX5-45 GNSS/INS is an excellent match for measuring attitude (pitch, roll and yaw), position (latitude and longitude), and velocity in a variety of applications including antenna pointing, platform stabilization, flight tracking, navigation and regime monitoring. It allows a greater degree of precision by moving through terrain in 3D with a GNSS-aided navigation system when a GNSS signal alone is not accurate enough. The entire GX5 product line features extremely stable and low-noise gyros, a new accelerometer with noise densities as low as 25μg/√Hz, a multi-constellation GNSS receiver.

“The GX5’s footprint is the same as its predecessor at approximately 44-mm-by-36-mm-by-11 mm, and it weighs less than 20 grams,” says Martin. “That makes it the smallest, lightest, and highest-performing inertial sensor in its class, which allows the payload to be used for more important things such as increased fuel range, heavier camera for better images, and faster servos for antenna pointing. Every gram you can shave off a sensor, you can add in payload.”

The sensor is easily integrated into customer systems, allowing users to quickly drop it into their existing application. It shares the same miniature footprint and API as LORD Corporation’s earlier inertial line and has the same mounting, connector and software as well as its high reliability.

“Every GX5 is fully calibrated and temperature compensated by our proprietary third generation robotic calibration equipment,” says Martin. “We have optimized these sensors for real-world conditions to maintain reliability and withstand high variations in temperature and shock.”

For more information, call 1-877-275-5673, email sensing_sales@lord.com or visit www.MicroStrain.com.

About LORD Corporation

LORD Corporation is a diversified technology and manufacturing company developing highly reliable adhesives, coatings, motion management devices, and sensing technologies that significantly reduce risk and improve product performance. For more than 90 years, LORD has worked in collaboration with our customers to provide innovative oil and gas, aerospace, defense, automotive and industrial solutions. With world headquarters in Cary, N.C., LORD has approximately 3,100 employees in 26 countries and operates 19 manufacturing facilities and 10 R&D centers worldwide. LORD actively promotes STEM education and many other community engagement initiatives. For more information, visit http://www.lord.com.

# # #