- Posted Monday, February 3, 2020 - 10:30

Maximizing uptime with intelligent vibration monitoring and predictive analytics

Application Study - Understanding critical component performance

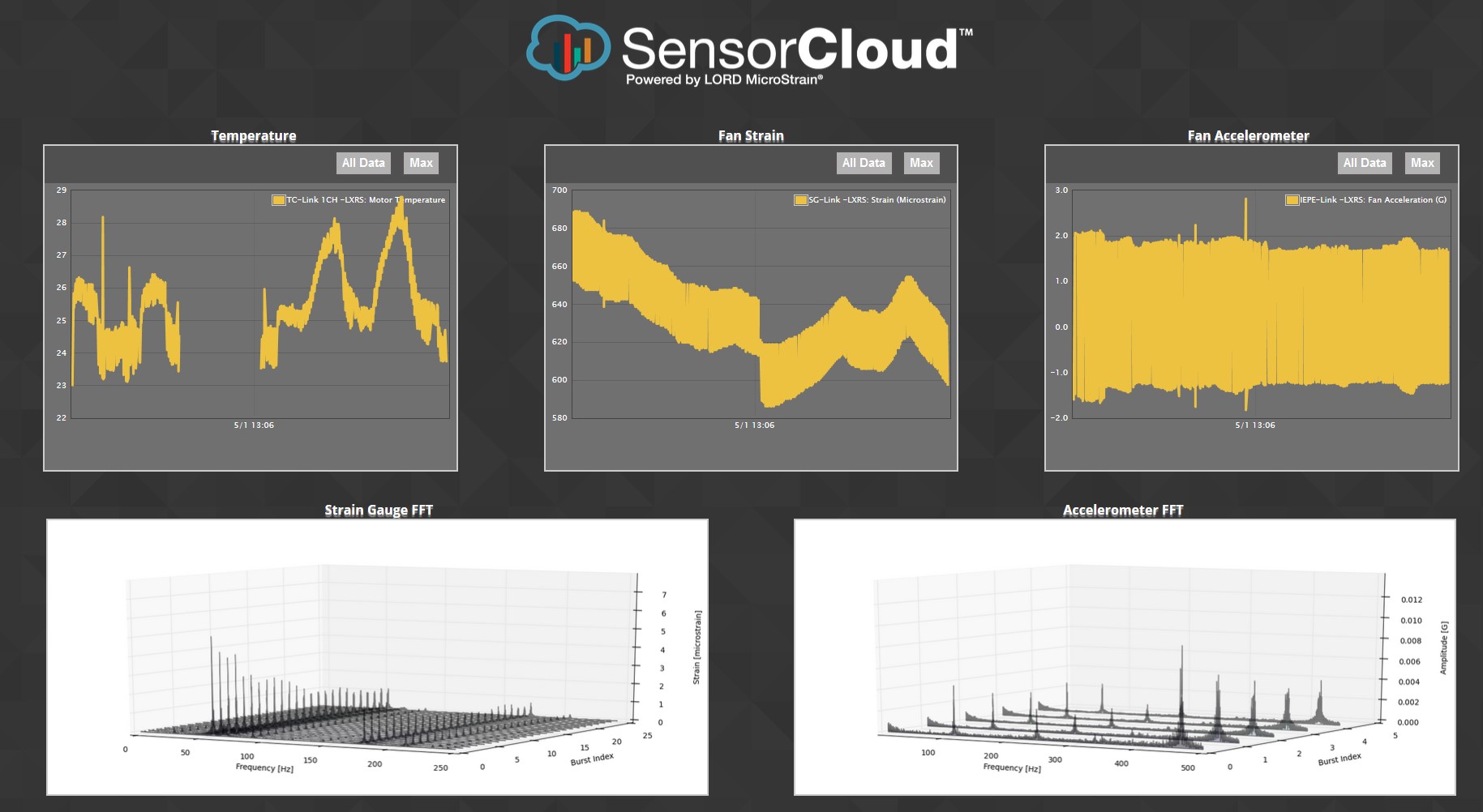

Using real-time monitoring to understand in-service machine vibration keeps machines running; allowing predictive instead of reactive maintenance, as well as historical trend analysis and comparisons between machines and operating environments.

Real-time alerts and historical analysis - Using SensorCloud with the MathEngine analytics tool provides characterization metrics between machines and operating environments, through the equipment life-cycle.

Machine health monitoring - Measuring in-use vibration of factory equipment allows predictive maintenance in high-value production processes.