- By

- Posted Monday, January 20, 2020 - 09:15

Aircraft flight test has traditionally been expensive and time consuming to accomplish, requiring complex hardware design and integration and extensive operational test teams to address aircraft downtime for instrumentation maintenance and calibration,

Dan O’Neil, LORD MicroStrain®

Steve Low, Boeing Military Aircraft

Background

Aircraft flight test has traditionally been expensive and time consuming to accomplish, requiring

complex hardware design and integration and extensive operational test teams to address aircraft

downtime for instrumentation maintenance and calibration, flight operations, and post-flight data

handling and evaluation.

Recently, elements of Boeing Military Aircraft flight test and LORD MicroStrain worked jointly

to conduct a flight load, vibration, and thermal survey of a Boeing S-100 autonomous rotorcraft

using a suite of MicroStrain wireless sensors and inertial devices. This program

represents a technology breakthrough wherein an autonomous rotorcraft flight test program

utilized only wireless sensors within synchronized networks to collect flight data of interest.

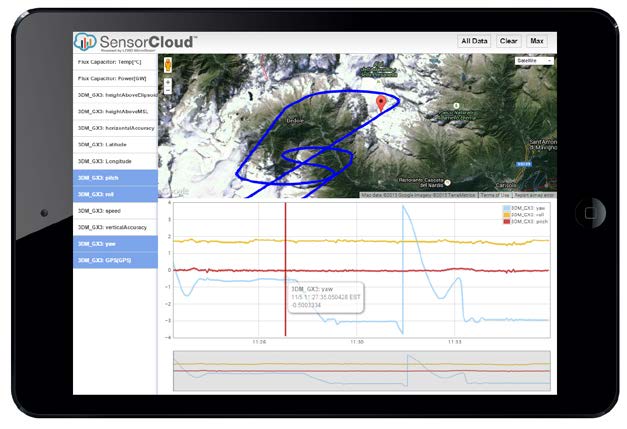

In addition to the successful collection of high quality data, the Boeing team was able to

accelerate the flight test program with significantly reduced expense by leveraging off-the-shelf

wireless technology. The wireless nature of the comparatively affordable technology allowed a

minimally-invasive integration onto the flight vehicle, and MicroStrain SensorCloud™ analytics

enabled a single team of limited personnel to make go/no-go decisions based on nearly real-time

data evaluation. This approach provided augmented decision efficiency, which accelerated flight

test execution by allowing multiple daily sorties and concurrent data analysis.

The Aircraft

The S-100 Camcopter platform is an unmanned Vertical Takeoff and Landing (VTOL) aircraft

produced by Schiebel of Austria (Figure 1). This autonomous rotorcraft is capable of flying with

a 50 kg payload for up to a six-hour loiter time with a service ceiling of 5400m. Operators can

control the aircraft in real-time via a ground-located control station, or the aircraft can fly a

preprogrammed mission completely independent of operator intervention. Boeing Mesa is the

current US-based distributor, and it conducted a flight test program for the S-100 to better

understand and characterize effects on flight critical dynamic and structural sub-systems.