Aircraft & Helicopter Health Monitoring,

Condition Based Maintenance, and Navigation

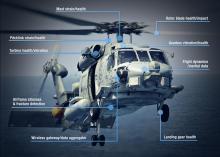

MicroStrain's advanced sensor systems are extensively deployed on commercial and defense aerospace platforms, including helicopters, unmanned aerial vehicles (UAVs) and commercial aircraft. Our synchronized wireless sensor networks feature fully-calibrated miniature sensors and extended range communications for use in a variety of applications, including health monitoring and management, predictive maintenance and navigation.

MicroStrain’s wireless sensor networks will help ensure integrity, safety, and reliability of aircraft, rotorcraft and rotating components by assessing long-term performance and preventing costly repairs and downtime while our miniature, lightweight inertial sensors can be deployed in a variety of defense and commercial platforms to improve the accuracy and reliability of aerial navigation and tracking.

Asa Davis, Zach Fuchs, Erin Gunn, Rachel Masters, Christopher Robertson, Benjamin Say, David Schenkenberger

Drones already have their own internal IMU's, but those IMU's lack the accuracy needed for larger flight tasks. For shorter flights and recreational flying, the internal IMU is precise enough to keep the drone running as expected. A

Ian Moore, Field Application Engineer

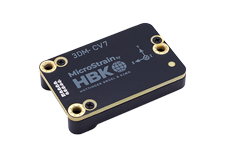

The new 3DMGQ7-GNSS/INS builds on the success of the 3DMGX5-GNSS/INS and adds many features desired by customers which resolve common challenges in specific use cases. This test report highlights four evolutionary improvements.

Thiago A. Rodrigues, Jay Patrikar, Bastian Wagner, Sebastian Scherer, Constantine Samaras

Parker LORD sponsors research to model energy consumption for quadcopter package delivery drones

Ian Moore, Field Application Engineer

This report compares the steps necessary to use magnetometer vs dual-antenna as a heading source for a Cessna 150M flown in a repeated flight profile.

Technology evolves as we improve how information is gathered, analyzed and implemented into various applications. For instance, Vertical Takeoff and Landing aircraft (-VTOL) can take off, hover and land vertically.

Parker Hannifin MicroStrain

Patented Near Field Communications and Power for Wireless Torque Monitoring

Authored by Arms et al., and featured in American Helicopter Society: 2006

Wireless sensor networks with integrated energy harvesting capabilities demonstrate autonomous helicopter pitch link monitoring and condition based maintenance for NAVAIR.

Authored by Arms et al., and featured in American Helicopter Society: 2007

MicroStrain’s wireless sensor system is demonstrated in flight tests for direct load monitoring on Bell M412 rotating components along side energy harvesting and energy aware operating modes.

Authored by Arms et al., for Australian International Aerospace Congress: 2011

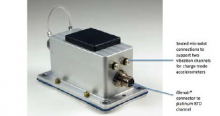

Synchronized wireless and hard-wired sensor network on rotating components includes energy harvesting to eliminate battery maintenance and improve SHUMS on Sikorsky MH-60S.

Parker MicroStrain

A distributed network of MicroStrain’s wireless sensors and its cloud-based data management portal, SensorCloud, were used by NASA to monitor the affects of acoustic shock on Kennedy Space Center equipment.

MicroStrain

Sensors for Displacement Measuring

MicroStrain

Optimize communication, data analysis, and battery life with a Wireless Network

Parker MicroStrain

D. O'Neil, MicroStrain; S. Low, Boeing Military Aircraft Corp.

Immediate data feedback allowed flight engineers to make critical adjustments shortly after each test, enabling multiple tests per day. Previous test programs required week-long delays between flights for data analysis.

Dan O'Neil, Steve Low

Aircraft flight test has traditionally been expensive and time consuming to accomplish, requiring complex hardware design and integration and extensive operational test teams to address aircraft downtime for instrumentation maintenance and calibration,

D.Wells, A.Westland; T. Frattini, AgustaWestland; D.Churchill, S. DiStasi, Parker MicroStrain Sensing Systems

Development of a helicopter on-rotor HUM system powered by vibration energy harvesting

D. O'Neil, C. Townsend; MicroStrain, C. Hodgkins, NAVAir Pax River

Effective and accurate torque monitoring has been, and will continue to be, an ongoing challenge in the industrial, agricultural, and aerospace arenas. Torque measurements are useful as an indicator of mechanical system health and desirable for test and p

Authored by Arms et al., and featured in American Helicopter Society: 2009

Integrated structural health monitoring and reporting system for use on pitch link of Navy Bell M412 helicopter synchronizes distributed miniature sensors and active RFID in a low-power network.

MicroStrain

Instant, comprehensive reporting of aircraft health, from nose to rudder

MicroStrain

MicroStrain’s distributed rotorcraft wireless health monitoring systems provide a wealth of information about aircraft component health and usage.