Structural Health Monitoring,

Condition Based Maintenance & Predictive

Maintenance

MicroStrain's cost-effective wireless sensing solutions enable a broad suite of monitoring, testing, and measurement applications. Our expertise in long-range wireless sensor communication, progressive power management, and cloud-based sensor data management enable accessible, long-term monitoring of machines, buildings, vehicles, bridges, wind turbines, conveyor belts and other high value assets.

With MicroStrain’s wireless sensor networks, structural health monitoring, condition based maintenance, and predictive maintenance can help ensure integrity, safety, and reliability of machines, buildings and structures and more while efficiently and cost-effectively assessing the long-term performance of structure and machine components and preventing costly repairs and downtime.

Asa Davis, Zach Fuchs, Erin Gunn, Rachel Masters, Christopher Robertson, Benjamin Say, David Schenkenberger

Drones already have their own internal IMU's, but those IMU's lack the accuracy needed for larger flight tasks. For shorter flights and recreational flying, the internal IMU is precise enough to keep the drone running as expected. A

Ian Moore, Field Application Engineer

The new 3DMGQ7-GNSS/INS builds on the success of the 3DMGX5-GNSS/INS and adds many features desired by customers which resolve common challenges in specific use cases. This test report highlights four evolutionary improvements.

Ian Moore, Field Application Engineer

This report compares the steps necessary to use magnetometer vs dual-antenna as a heading source for a Cessna 150M flown in a repeated flight profile.

Technology evolves as we improve how information is gathered, analyzed and implemented into various applications. For instance, Vertical Takeoff and Landing aircraft (-VTOL) can take off, hover and land vertically.

Parker Hannifin MicroStrain Sensing

MicroStrain Wireless Sensor Network and Displacement Sensors Measure to sub-micron accuracy .

Parker Hannifin MicroStrain

Patented Near Field Communications and Power for Wireless Torque Monitoring

Parker MicroStrain

Inertial Sensors take wave motion out of the Geological Survey of Israel Dead Sea Eddy Covariance evaporation study

Sydney Trains

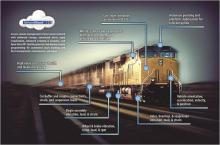

Wireless sensors provide safe standoff from high voltage train power

LORD MicroStrain

Non-intrusive solutions to measure high-speed rail infrastructure conditions

LORD MicroStrain

Maintenance and service is a key contributor to the total cost of train ownership. LORD MicroStrain® wireless sensing systems provide fleet operators with a quick and cost-effective path to embedding health sensing capabilities on both new and existing cr

LORD MicroStrain

The ongoing maintenance and operation cost can approach $200,000 per mile of high-speed train track annually. LORD MicroStrain® wireless sensing systems provide fleet operators with a quick and cost-effective path to embedding health sensing capabilities

Authored by MicroStrain Inc.: 2011

Cost effective inertial sensors demonstrate accurate dead-reckoning positioning in two and three dimensions for more precise and reliable personnel tracking.

Authored by Arms et al., from MicroStrain, Inc.: 2003

Embedded wireless sensors powered by an external magnetic field measure temperature, strain, crack extension, and dielectric constant of a composite during autoclave cure process.

MicroStrain 2020

MicroStrain's wireless sensor network and cloud-based data management platform enables growers to remotely monitor environmental variables across multiple locations.

Authored by Galbreath, J. et al., at MicroStrain, Inc.: 2003

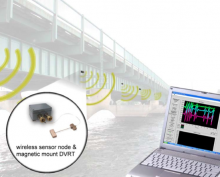

High-speed wireless sensor network with user-triggered and event-triggered data streaming capabilities enables long-term bridge interrogation under numerous operating conditions.

MicroStrain

MicroStrain G-Link-200-R provides ASTM F2137-18 Standard Amusement Ride Characterization Test capability.

MicroStrain

Sensors for Displacement Measuring

Authored by MicroStrain Inc.: 2012

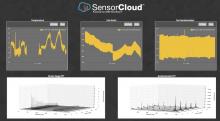

MicroStrain wireless bridge monitoring systems enable long-term performance diagnostics with energy harvesting and remote cloud-based data analytics.

LORD MicroStrain

MicroStrain’s 3DM-DH3™ downhole sensor is an obsolete product. The application note is included for historical reference

Using real-time performance monitoring to understand in-service product durability and provide customers with value-added predictive maintenance sets OEMs apart from the competition.

Authored by Arms, A. et al., for Structural Material Technology: 2004

Remote sensing network comprised of low power miniature sensors and cellular interface enables scalable structural monitoring with two way communication for adaptable data collection.

Parker MicroStrain

BridgeComposites, LLC of Hornell, NY uses a LORD MicroStrain wireless bridge monitoring system to evaluate seismic isolation bearings.

Parker Hannifin MicroStrain

Wireless environmental sensor network provides a scalable monitoring technology for reporting and analyzing distributed data center conditions in real time-for optimized operation and reduced cost.

MicroStrain Sensing Systems: 2020

MicroStrain Sensing Systems wireless sensor networks and cloud-based data management platform enables growers to remotely monitor environmental variables across multiple locations.